Table of Contents

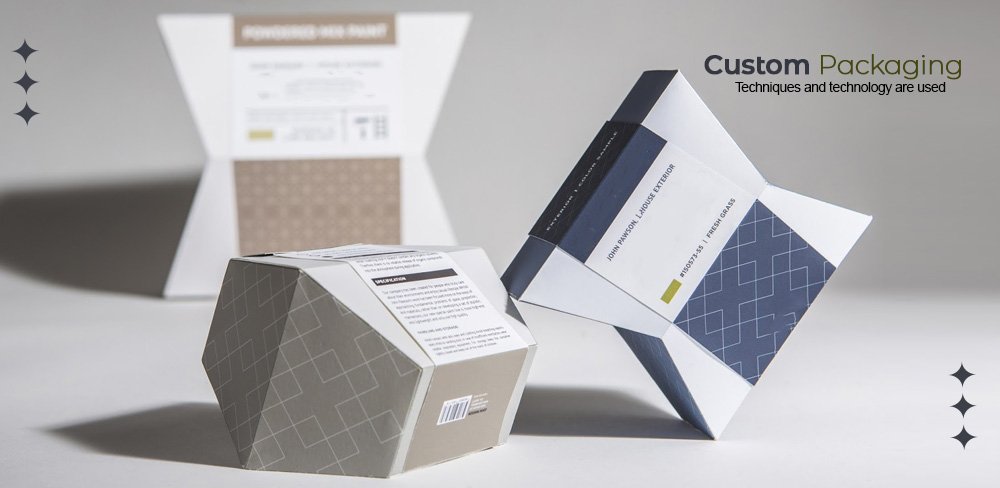

The product packaging can showcase the worth of a brand. Thus, when choosing to package, most brands go above and above. The use of custom packaging can help a brand’s reputation and customer base grow. Modern technologies have come into the market. Packaging producers are using them to offer their customers the highest caliber packaging. They create alluring packaging to entice consumers to brands. Do you have any knowledge of the various manufacturing methods for packaging? Several procedures are important, including die-cutting, printing, scoring, and finishing. They are important procedures in the packaging manufacturing process. Here, we’ll discuss many techniques and technologies to manufacture custom boxes.

Techniques To Create Innovative Shapes Of Custom Packaging

The methods and resources listed below can help to design custom boxes in unique shapes.

Die-Cutting Tools And Assembling

We are aware that precise box shapes can influence buyers. It is also difficult to execute by hand when making novel box shapes. Thus, to cut sheets into box flaps, you must use die-cutting instruments. First, you must cut cardboard sheets or other materials into flaps. While cutting, you should keep in mind your desired size and shape. After that, you must put these flaps together using the design template. These boxes come in a variety of shapes. All brands need to have attractive and respectable shapes. Thus, die-cutting instruments are important for producing outstanding box shapes.

Special Add-Ons

According to the requirements of the items, many box kinds have different add-ons. You must realize that these add-ons make these boxes more practical. Custom inserts and placeholders support the holding of the appropriate products well. They reduce their mobility. Thus, they shield them from different injuries brought on by shocks and bumps. These boxes may include die-cut windows, several internal segments, and other extras. For these extras, packaging producers use die-cutting machinery or other tools.

Why Are Die-Cutting Tools Important?

The significance of die-cutting instruments is important to discuss. A brand is first perceived through its product packaging. Thus, every brand needs to make a memorable first impression. The visual appearance of custom packaging sleeves depends upon the shape. Other add-ons to the boxes also influence their visual catchiness. These shapes need to be correct.

Moreover, custom inserts or placeholders must be in precise shapes to leave a nice image. The best way to design precise and eye-catching box designs are with die-cutting tools. Hence, die-cutting tools are important to create accurate and precise shapes.

The Way Of Printing Custom Packaging

For many reasons, printed boxes are significant. The following printing methods are crucial and popular among different brands.

Offset And Screen Printing

In the market, offset and screen printing technologies are significant and well-liked. Their contribution to producing top-notch printing outcomes is their main perk. To make an impression, the printing’s quality is a crucial factor. Thus, all brands must select outstanding procedures to deliver superior printing results. Keep in mind that screen printing and offset printing technologies are expensive. They are only useful if you need to print many boxes.

Digital Printing

Digital printing is another well-known printing technology. Additionally, it delivers the best printing results. Moreover, it aids in creating a favorable impression on customers. Digital printing can be your best bet if you only need to print a few boxes. This technology’s decreased cost is by far its most significant advantage. Thus, everyone can afford it.

Why Are These Techniques Important For Custom Packaging?

You must be aware of the significance of printing quality. Never forget that your company’s worth depends upon its premium packaging. Thus, to win over your customers’ approval, it must be impressive. Brands can achieve an excellent first impression on clients with premium quality printing. These methods can contribute to producing outstanding printing results. This fact makes them important. Most companies use these technologies to produce stunning and high-quality printed boxes. While pictures should be clear, text details must be simple to comprehend. Thus, these technologies are critical for delivering top-notch printing outcomes.

Custom Packaging Finishing Techniques

Box surface finishing has the potential to change how customers react. Different brands may use various box finishing techniques. Here are a few popular ways to finish boxes to give them a luxurious feel.

Coatings

The visual appeal of custom packaging boxes can be improved with extra coatings. Coatings come in a variety of forms, such as gloss or matte. Using gloss coating is the best method for making your boxes look shiny. Furthermore, a matte finish can create a more muted and earthy appearance. Thus, because of their extra coatings, these boxes can aid in impressing individuals.

Foiling

By employing various strategies, all brands must make their packaging stand out. Do you understand the value of foiling? It may give your packaging a metallic feel. Whenever you present your consumers’ products in metalized boxes, your customers will feel good. Moreover, different varieties of foiling exist, including gold, silver, and copper foiling. This will make your boxes stand out in retail outlets and draw in new customers.

Embossing

Lifting text or pictures over the background is popular among brands. Text or graphics appear adorable when you raise them against the background. Thus, you can apply this approach to imprint your brand’s name, logo, and graphics. Hence, these boxes’ stunning appearance will increase sales because of their embossed elements.

How Can Finishing Techniques Be Helpful?

You must understand the significance of these methods. It is a reality that the packaging design for premium boxes needs to be appealing. You can attract more individuals with premium quality packaging. Your boxes could seem unique from other boxes on the market if you use these finishing options. Thus, more individuals will contact you to learn more information. Thus, enhancing the visual appeal of boxes through finishing options is crucial. They may result in a larger clientele and better product sales. The process of making boxes involves many strategies. We have discussed the many methods used in this manufacture. Hence, printing and finishing options are also crucial to raise the value of these boxes. We have observed a variety of methods popular among manufacturers of premium packaging. You may comprehend how and why these techniques are important. Thus, you must use them to make the best quality custom packaging

Also Read:

https://www.newsniz.com/what-are-the-right-superior-packaging-materials-for-rigid-boxes/